Donna Sanders is the script supervisor, field producer and food editor for Where The Food Comes From.

This is her Behind-The-Scenes look at our day filming at Braswell Family Farms in Nashville, NC.

Talk about making an impression. There are so many facets to this story I don’t know how to begin. There is history, security clearance, nutrition experts, sterile procedures like I have never seen before, and something I consider a little creepy. Intrigued? I hope so.

Where The Food Comes visited Braswell Family farms in Nashville, NC. in May and host and producer Chip Carter was about to get an experience of a lifetime! In fact – we all were. And before we even left our home state it started.

Braswell Family Farms is the second-largest Eggland’s Best franchise. But like anything else it did not start out that way and, with that said, get ready for brief history lesson – promise I will keep it short. Its humble beginnings started in 1943 when brothers and first-generation farmers E.G. (Eugene) Braswell and J.M. (Joseph) Braswell purchased Boddie Mill and began grinding cornmeal for local farmers and neighbors.

In 1950 they purchased an old mill in Nashville, NC forming Braswell Milling Company and establishing a custom grind and feed mill business. Kids grow up and wars are fought. Enter second-generation brothers Gene Braswell and Ronald Scott Braswell, Sr. who joined the family business following their tour in the military. They expanded the business in the 1960s to include raising laying hens and producing high-quality shelled eggs. Okay things may start getting a little tricky and bear in mind there are other Braswells running around.

In 1975 third-generation Ronald Scott Braswell, Jr. (Scott) purchased Red Hills Farms and built three egg houses to help meet the demands of the growing Braswell business.

But the pivotal moment came in 1991 when Scott Braswell had the foresight to invest in the beginnings of an Eggland’s Best franchise. And this is what makes Braswell Family Farms a leader in the highest standards of quality and consumer confidence. Whew, and you haven’t even been introduced to fourth-generation Trey Braswell yet.

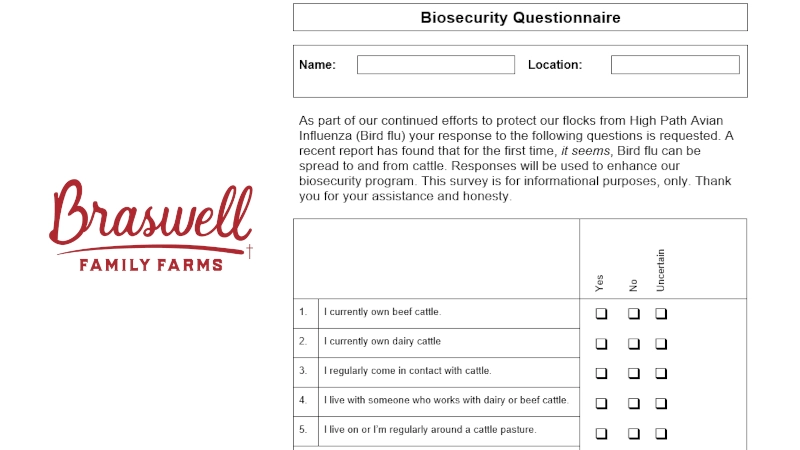

Being a nurse I have had many background checks before working in hospitals, teaching at a nursing college, and as a TV producer I’ve been cleared to visit The White House and U.S. Capitol. But I have never had to have security clearance for a shoot.

Before we left for NC, Chip and the entire crew had to complete a biosecurity questionnaire attesting to the fact we had not been around cattle and were told, “No one from your team or the WTFCF team can be around any birds of any kind (including pets) for a minimum of 72 prior to arriving at any of our facilities.” Sounds a bit over-the-top, but okay and the questionnaires were sent back. What I didn’t realize at the time was how prudent this actually is.

On shoot day, we were up before the chickens to meet feed and nutrition manager Jackie Bunch at the Braswell office to finalize the day’s activities. As a nurse, sterile technique and conditions are extremely important to me, but this one caught me by surprise. Before we could even walk in the office we had to step in a footbath and use a spray shoe sanitizer. And there wasn’t even a chicken in sight!

Jackie Bunch & Chip Carter

Chip’s first interview takes place with Jackie in the control room, outside by the equipment used to hold the feed and the corn shed. And naturally the question — which came first the chicken or the egg? — came up.

Actually – it’s neither. Jackie told Chip the feed comes first because to build a better chicken to get a better egg you have to start with a solid feeding program. That makes total sense. Poultry requires a diet that contains a mixture of fats, proteins, carbohydrates, vitamins, and minerals. And it is her job to make sure all of this is perfectly combined down to the finest grain. The Braswells have gotten so good at it they actually have a second business selling feed to other farmers.

David Cooper, Chip Carter & Jackie Bunch

Braswell’s chicken feed is 50-60% corn and is tested to ensure the quality from various corn crops is the same and the water content critically cannot exceed 16%. It is panel operator David Cooper’s job to actually weigh the corn and perform this analysis.

Other ingredients will vary because different chickens require different nutrients. Who knew? And like baking the finest cake all feed ingredients are weighed. Fun Fact 1: Marigolds and alfalfa give egg yolks that bright gold-yellow color we all love. Fun Fact 2: The thicker the egg shell the greater the calcium content of the egg.

Folks poultry feed is such a science and one I cannot even begin to do justice to. But just the idea there are poultry nutritionists is totally mind blowing.

The Braswell Family

Remember I said we were up with the chickens? It wasn’t exactly lunch time but it was time for breakfast and it was at a local diner we first meet President and Chief Executive Steward Trey Braswell and Ownership and Advisory Steward Scott Braswell. You will hear more about them in a minute.

Next to the diner there was a grocery store. I like grocery stores that are out in the country because they usually have things I can’t get at mine. I had a blast picking out penny candy from the barrels while Chip ran around talking to everybody. Yeah, that comes kind of natural to him.

Chip decided to open the show holding a carton of eggs. Judging from the above picture you can tell how successful he was. I will admit I like when he botches something up or, in this case, drops a dozen eggs. It keeps the show personal and humble – true reality programming. Chip agrees and will never allow the editors to cover his tracks while putting together an episode.

First Stop – Boddie Mill, built in 1834 and, as I mentioned earlier, purchased by the Braswells in 1943. Inside you can still see the holding containers for the grain and a few other artifacts. Some of the crew braved going up to the second and third levels, but not me — narrow steep stairs are a danger to my health.

I am not too sure who told me, but the Braswells will be putting a fence around the property to stop the vandalism that has been happening. It hurts my heart to think people intentionally damage others’ property, especially something that has so much history, significance and beauty.

Trey Braswell & Scott Braswell

Scott Braswell & Chip Carter

And it is here Chip interviewed ownership and advisory steward Scott Braswell. Remember, it is third-generation Scott who in 1975 purchased Red Hills Farms to help with the growing demand of the business and in 1991 he became president of the company. You will hear more about it during the interview.

I’m sad to say that since filming this episode Mr. Braswell passed away. He left behind a legacy of dedication, leadership, and transformative impact on the company he helped shape into what it is today.

The property around the mill is so gorgeous and was just begging me to take some pictures. So I did what I do best and wondered off.

I left the mill and walked across the Gene E. Braswell bridge and went under it. If the name sounds familiar it was named after the Gene Braswell who bought the mill in 1943. Yeah, I probably should have thought that one through. There was an incline and a lot of loose rocks but I really wanted to get some good pictures.

This picture is from under the bridge of the waterfall next to the mill that supplied the energy for the millstones to grind the grain all those years ago. Such a tranquil setting and I am happy to say I didn’t see any snakes.

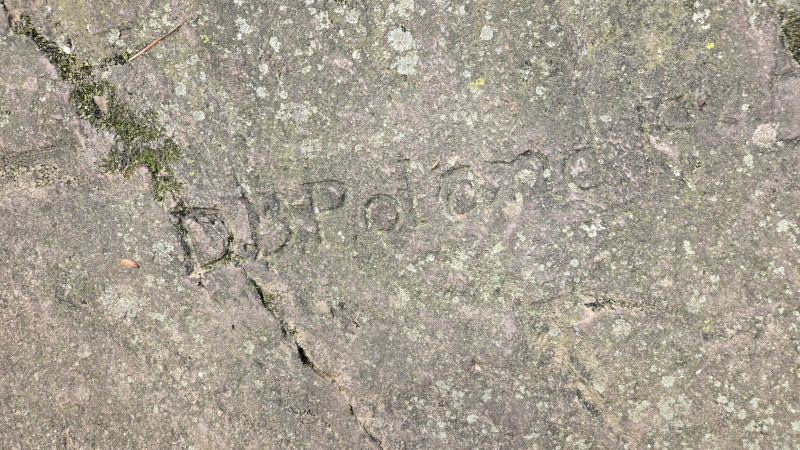

I don’t remember who was with me, but they brought my attention to a carving in the old cement under the bridge. It dates back to 1940, when a man by the name of Dr. Poland engraved, “Where will we be for eternity neighbor.” It is fascinating where little messages can be found. Fun Fact 3: The Braswell family periodically has the stone cleaned.

Up next is probably the craziest thing I have ever done and this includes climbing a 90-foot crane at the Port of Savannah in Season 3, Episode 11: Why Is There A Seaport In A Show About Farming? If I didn’t have to, I may not have. But it was time to meet the chickens in… not in a chicken coop, but what I would call a chicken mansion! And what we had to do made the personal protective equipment and procedures at the hospital pale in comparison.

All of us had to put on shoe covers and knee-length heavy duty plastic boots. But the shocker was when blue hazmat suits were handed out. Yes folks, all of us were given thick hazmat suits which completely covered us from head-to-toe. Hairnets are mandatory, and so are N95 masks. I haven’t really worn a N95 since the last time I went into a patient’s room that had TB. Now, I am beginning to get a little creeped out – just a little.

Are we ready to enter the chicken mansion? Almost; first hand hygiene and with plastic shoe covers on we had to step in another disinfectant foot bath. I forgot to mention, we also had to change our street clothes before and after our visit to the chicken mansion. The logic for all these precautions is simple – the Braswells don’t want anything brought in and nothing brought out. I think I can safely challenge any germ to attempt it.

Ready or not – in we go. We walked into a huge area filled with 11,000 chickens who were just wondering around. They moved out of our way as we came in but not for long. It was a bit warm inside, on the dimmer side, and very very loud! You can imagine what 11,000 clucking chickens sounds like. Fascinating yes, creepy yes – liking it, not so much.

Now I have been around chickens and have learned to watch where I step. But the chicken mansion did not seem to have an excessive, excuse me for this, poop problem and we were able to sit down on the benches. I sat down, but thought to myself how long are we going to be in here? The answer – as long as it takes to interview president and chief executive steward and fourth-generation Trey Braswell.

Chip Carter & Trey Braswell

Trey earned a bachelor’s degree in business administration from North Carolina University and rejoined the family business in 2008. In 2017, due to health issues, Trey’s father Scott handed the company over to him. Trey rebranded the business Braswell Family Farms. You can imagine how hard it was to hear the interview but I did pickup on a couple of fun facts. And rest assured you will hear it all in the episode.

Did you know a chicken lays one egg per day? And hold onto your hats, the color of the egg is determined by the color of the chicken’s earlobe. Really! It never occurred to me chickens have earlobes, but they do and they are under the feathers on the sides of their heads, but I had no desire to check for myself. Fun Fact 4: While there are always exceptions, dependent upon variety and genetics, chickens with white earlobes will lay white eggs and those with red earlobes will lay brown eggs.

As big as the chicken mansion is, the actual coops where the eggs are laid is small. The chickens prefer a dark and small cozy place to lay their eggs. Turns out the chickens follow each other in and out of the small coops and take turns using them. Ah, so that’s why there aren’t dozens of eggs lying around.

Next question, but why aren’t there any eggs in the little coups? Believe it or not the newly laid egg goes through a hole in the small coop, onto a belt, and is immediately transported to the processing plant where it is washed and disinfected, inspected and packed. Another safety measure! The egg never touches a human hand.

Chip and Trey are still talking and the chickens are getting curious and start coming up to us pecking at our shoes and shoulders. Honestly, at this point I am quickly getting over being in here. Talk about sensory overload.

Finally, it was time to leave and I was able to change into my other set of clothes outside behind a trailer. I was getting ready to put my bagged-up clothes in the trunk when another person came to the car with a huge canister and hose. Truly, they weren’t going to spray us, were they? No not us, but they did spray the car tires with another special disinfectant – I do wish I had gotten a picture of that.

Onto the packing house. As we were driving up to the plant the car had to go through a bumper-to-bumper sanitization sprayer. Again, I am grateful it was the car and not us, but there were more shoe sanitizer machines.

The video above shows the eggs as they arrive at the processing plant and are going through the washing and disinfectant process. From this point things got a bit tough for me to photo or shoot video because it was all done inside machines.

The eggs undergo an assessment with UV light to look at the yolk, the white and the size of the air cell in each egg. The better the exterior and interior of the egg looks the better its grade. With the use of robotic arms, the eggs are further sorted by weight and packed accordingly. Like I said, there was a lot going on.

Willie Jervis

Our last interview of the day was with Director of Transportation and Processing Willie Jervis. Willie told Chip the packing house processes 40 million dozen eggs plus per year.

What makes this packing house and Braswell’s eggs even more special there is a USDA Inspector who works right on the premises. And it is only the USDA that is certified to grade eggs. For an egg to be USDA certified it has to have the highest standards and you can tell because the official seal is on the packaging. And I am happy to say Braswell Family Farms eggs and Eggland’s Best are both USDA approved – believe me I checked. Approved by the Braswells, approved by USDA and approved by me!