American imports are massive. Everything from machinery, appliances, furniture, pharmaceuticals and so much more. Yes, we are even getting our prescription drugs from foreign countries. I realize it’s a global economy, but I also know we have to take care of business at home first. I don’t know about you, but for me, dependence on other countries is beyond scary, especially when it comes to our food: If we lose the ability to feed ourselves as a nation, we’re in real trouble.

Can there be such a thing as bringing something back from foreign producers? Short answer – yes.

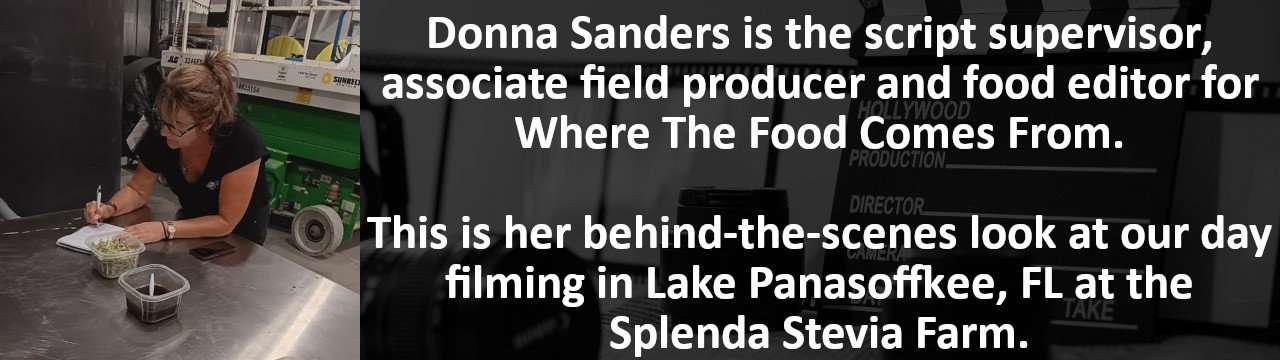

WTFCF visited Splenda Stevia Farms, owned by Heartland Food Products Group, in Central Florida on May 3 to tell such a story.

By now you are probably wondering, What does Splenda have to do with this topic or with farming? Well, until very recently, there was no production of stevia — a plant-based sweetener — in the U.S. It was all grown in other countries, primarily China. Rather than rely on foreign imports, Heartland Food Products Group has entered the farming business itself with a stevia farm in Central Florida that will supply the plants to create an entirely American industry in partnership with small family farms. In fact, all Splenda products are made in America. Pretty cool.

Ready for one of my digressions?

You may be asking what is the difference between Splenda and Splenda stevia? Splenda is the brand name for the lovely little sweetener found in tiny yellow packs. Splenda is made of sucralose and is 700 times sweeter than sugar. Both are great for similar purposes. For instance, you know regular Splenda is great for baking. But Splenda also makes a product called Magic Baker which contains stevia. It’s a 1 to 1 substitution so no calculating required. What a relief — there is something about cooking calculations that scares me and probably others.

Stevia is a plant-based sweetener, making it a great sugar substitute. Yes, the plant does have to undergo mechanical processing, but it remains a naturally derived sweetener. The process extracts a syrup, which is where the sweet stuff is — same as mashing and boiling sugarcane to make sugar. I do attempt to explain the process further down in this article, but rest assured you will see this during the episode. Splenda stevia can be found in green packets with the same logo as the familiar yellow packets — and it’s 300 times sweeter than sugar. Back to the show.

My day began by briefly meeting Ted Gelov, Chairman and CEO of Heartland Food Products Group. He was not there to be interviewed. He was there to check on his employees, meet with us and other visitors, and keep the positive team attitude flowing.

Heartland is family owned and is a patriotic company that promotes America-first. You can see it in some of their logos proudly featuring the Red, White and Blue. You’ll hear more about their grand plan to help American farmers in the episode. Hint: It has to do with an economic opportunity for small family farms.

All our interviews take place with Ricardo Reyes, EVP, Global Manufacturing, Quality and R&D, who flew in to meet us for the occasion.

We drove out to one of the stevia fields to begin our day. It was here Ricardo told us about stevia and why Central Florida is ideal for growing this crop. Florida has long hours of daylight, the soil has good drainage – the sand helps – and there are not many days where a frost may occur. All of these factors provide the perfect growing conditions for stevia.

Stevia has a bubblegum-ish texture when chewed and tastes very sweet. Chip couldn’t resist sampling a few leaves off a plant. Unfortunately, instead of spitting it out, like Ricardo recommended, Chip swallowed it. He attempted to continue the interview but started choking instead. And kept choking. And kept choking. We were all laughing, including him — there was no danger, but it took several minutes for Chip to get it back together. That big mug you see in the picture? That’s Chip’s constant companion — good thing, as it took quite a few chugs before he was able to clear the leaf from his throat. Problem resolved so on with the shoot.

Off to the extraction plant. The facility was immaculate, but unfortunately you couldn’t see inside the vats. This was a problem for me. If I could not see inside the vats how was I going to take pictures? Don’t worry, I have a simplified explanation and our cameramen weren’t afraid to scale the heights and head up ladders to get a peek at the process — the episode will fill in the blanks. Dried stevia leaves are harvested then soaked in water to get the sweet substance out of the leaf. This liquid is then filtered, purified, dried, and crystalized. Sounds easy right?

Chip’s demonstration of the process is much more entertaining. The hands you see in the episode coming in from the side to hand him the containers showing the varying stages of the process? Well, let’s just say I was really happy my nails looked good — and so was our guest Mary Days.

In front of the extraction plant is a gorgeous lake. As a bonus you can see the stevia fields behind it. There was a beautiful breeze coming off of it and Mary and I just stood there taking it all in. But there is a purpose to the lake. Remember I said how much Heartland and Ted Gelov care about the team? The lake was designed to give them a relaxing peaceful place to rest and rejuvenate during breaks and lunch. I really wish some of my past employers did that.

By now everyone knows how sanitary conditions are my pet peeve and this farm measured up to my standards, which are a holdover from my time in the medical world. From the cleanliness of the extraction plant, to the beautiful manicured fields, the same attention to hygeniene and sanitation were apparent in the propagation area, where new stevia plants begin their journey. I do love a good propagation area! And especially in this case on a hot Florida day: The propagation area is located under a pavilion.

I had the brief pleasure of speaking with Lucas, the Propagation Manager, but unfortunately he got called away and many of my questions went unanswered. But one key one was. The question: “Why were the workers washing down the entire area before lunch?” As it turns out, before breaks and lunch the workers must thoroughly wash down all tables, benches, and equipment under the pavilion. This is done to ensure there will be no bacterial growth which could potentially lead to contamination. Points scored!

How does propagation take place? It starts with the mother plant, where stems are harvested below the nodes. The little stems are then placed in a growth solution to help with root formation. Finally, the stems are placed in a growth substrate to help sprout the roots. As always, Chip got in on the act.

The day was extremely hot and humid, and our next stop was awesome. You see, once the little stems are placed in the growth medium they are transported to a greenhouse.

Now for the best part. The greenhouse has misters. We all had the opportunity to walk in and let me tell you it felt wonderful. Such a relief from the hot and humid weather. We were concerned about the cameras getting wet, but the cameraman was able to get misted while still keeping the camera dry. Chip got to be in the greenhouse longer and ended the episode standing in the middle of the fine mist.

A long day of working and learning in the hot Florida sun came to an end with some welcome relief — we sat down in the shade and all shared some lovely cold lemonade and iced tea day… of course made with Splenda stevia!