The Time Machine

TIFTON, GA — Is it the year 1890? I don’t think so, but you’d never know it here at the Georgia Museum of Agriculture & Historic Village on the campus of Abraham Baldwin Agricultural College (ABAC). WTFCF visited April 20 for the annual Folklife Festival. We’ve all visited events like this at our local fairgrounds and elsewhere, but this living history museum established in 1976 puts all of them to shame.

The 400-acre park unfolds like the world used to — a small town with dirt streets and wooden porches leads to familiar country surroundings: a farmstead from 1870, a gristmill, a sawmill, a restored 1907 steam train. Simply amazing.

Several times a year, reenactors appear, and the whole village comes to life. That’s the show we went to make. Our resident 7-year-old, who also happens to be the host and producer of our show, was the most excited I’ve ever seen him.

All of the buildings in the park are original and were relocated to the ABAC campus. The farmstead at the edge of the small town represents the oldest farm in Southwest Georgia, dating back to 1870, but the “year we visited” was 1890, and all the events scheduled represented that era. Let the journey begin!

Before I take you through our day, let’s start with a little background. Covering 400 acres, this historic village is an outdoor museum with paths and unpaved roads leading to live exhibitions, demonstrations, and so much more. And I do mean so much more! The unpaved roads were okay to walk on, but the paths were a bit uneven. My advice – watch out for the tree roots. I had to be super careful, because I have a tendency to not look where I am going. I’m always in a rush.

Cravey House at the Georgia Museum of Agriculture & Historic Village in Tifton, GA

Unliked the author, these school children have no problems walking! Credit: Garret Boone

When we walked into the main foyer of the museum we were greeted by two women dressed in clothing from that era. (Interesting fact — most of the period costumes you’ll see here are handmade!) The display consisted of about a dozen tables all completely set in fine china, silverware, handmade candles and floral arrangements. An old-time spinning wheel and clothing completed the setting. However, it was the glassware that really caught my attention. But it was not the time to linger.

We were brought to the office of Garrett Boon, Director of the Museum of Agriculture & Historic Village. Garrett and Chip talked more about the exhibition while the crew checked their equipment. Now was my chance to go back and check out the beautiful tables.

There were about a dozen tables and I did not know where to begin. The two women who greeted us when we entered the foyer were curious about who we are and what we were doing there. I gave them a brief rundown. They thought it was amazing and eagerly shared the history of the tables, china, glassware, and silverware.

I was in glass heaven. So many amazing colors and styles. I could have stayed longer, but duty calls. Unfortunately I did not take a lot of pictures. I was afraid my battery would run low on my camera.

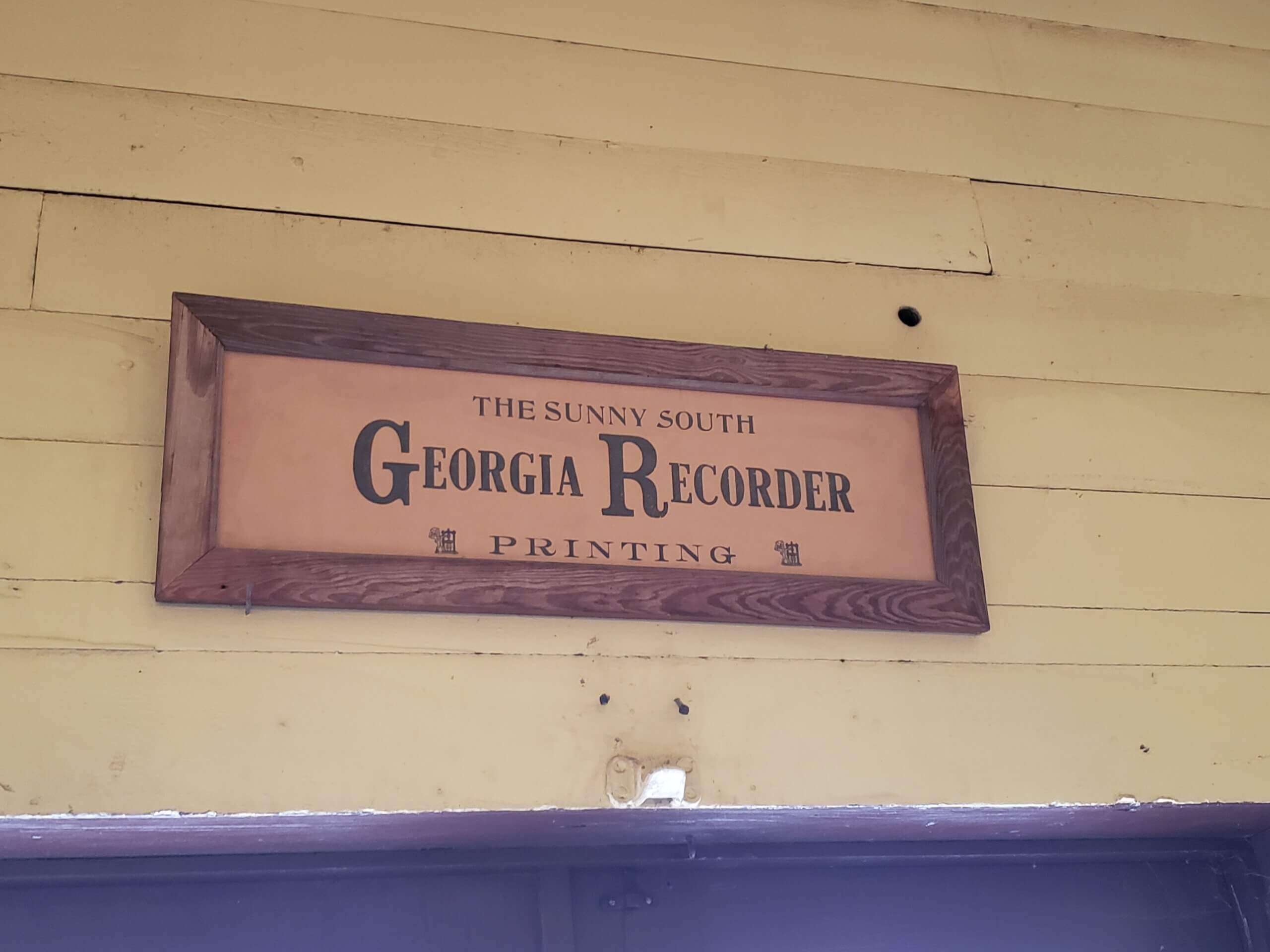

While the crew continued getting ready, my first stop was the newspaper office – The Sunny South Georgia Recorder Printing. This room was full of things I did not understand, but I did get a quick lesson. Chip did not go in, funny because he started his career in newspapers.

When I asked him why he did not go see the printing press he told me, “I didn’t know it was there.” Actually, that was a relief. We probably would still be in the Georgia Recorder. I could not hang around much longer because the crew was ready for cameras to roll at the sawmill.

Chip Breaks Something… Of Course…

The sawmill was very interesting, menacing-looking and, as you can imagine, very dangerous. Take a look at these circular saws! Reminded me of the scenes in old western movies where the heroine is tied to the saw belt. Personally, I think I could pass reliving a damsel in distress reenactment, but no one asked so we pressed on.

While the scene was being set up I wondered off and spoke with one of the volunteers on the other side of the mill. I was interested in the huge steam kettle, which was actually the boiler. This kettle is used to boil water creating steam to run the saws. No gas flames here, the boiler had to be filled with wood, which typically comes from the scraps of lumber being cut. And talk about hot!

It was so hot and loud it was hard to understand the answers to all my questions, never mind trying to take pictures. I think the reenactor said, “It requires 360 pounds of pressure to create the steam to operate the mill.”

Time to go back to that horrible looking circular saw. We met Keith Rouker, Volunteer Demonstrator/Reenactor of the sawmill. After Keith’s demonstration on how the saws work, our host and producer had to get in on the act.

Channeling his inner 7-year-old, Chip asked if he could run the saw. Keith was a little hesitant, but agreed. Keith’s initial thought should have stuck. While having a hay old-time running the saw, Chip decided to make it go faster and pulled down a bit too hard on the lever. Can you figure out what happened next?

Yeah, Chip jammed the saw!!! Like, really jammed!!! Like Keith almost cried jammed!!!

To his credit, Chip did not ignore this faux pas and hung around until Keith was able to fix it. On a side note: Our host did entertain the spectators for the 45 minutes it took to fix the saw. You have heard me say this before, and likely will again: Keith was probably glad to see us leave.

The Turpentine Mill

The path continues and here comes the turpentine mill. Another dangerous place. See the barrel on the left? That barrel could blow up if the turpentine gets too hot. The solution? Have a firetruck right next to it. To me this solution is a no bueno, a favorite expression of mine, and I really wanted to leave. But the show must go on.

What exactly does the turpentine mill make? Well David King, Volunteer Demonstrator/Reenactor gave us the answer. Standing many feet away I heard part of the conversation. Turpentine is used to make solvent, fuel and resin – used to make soap. I don’t think many women would appreciate that.

Reminds me of the lye soap granny made on The Beverly Hillbillies, but I digress. If you think about it with turpentine being a fuel and fuel being combustible, no wonder the firetruck was there.

David King, Volunteer Demonstrator/Reenactor

We visited the turpentine mill twice. First for the interview and the second time to put Chip to work. David even snatched Chip’s microphone and said, “We are going to change places.” Well the work is called the dipping process. What Chip did not know was how hard dipping actually is.

Dipping uses large steel spatulas to scoop up the liquid, put into buckets, and then into collection barrels to be moved to distilleries for processing. I really wish I had a personal picture of this, but I was holding a camera at the time and could not get the shot. But Jake Hallman, WTFCF Cameraman and Editor extraordinaire, did. Thank you Jake.

Chip said afterwards, “it was exhausting and hot.” I got the feeling this was one time he was happy to leave, and it’s impossible to get him out of anywhere.

At this point we all needed a break and restroom. Our next stop took us to the Wiregrass Feed & Seed, Vet Clinic, Pharmacy, General Store, complete with homemade ice cream, and a ton of candy and fudge. There was a mob sitting on the porches eating ice cream. We were offered some, but due to our crazy schedule we had to decline – sigh.

What I did not know was the tractor parade was about to start. The tractors are from many eras, owned by individuals, and stored in the garages of the museum. I was not prepared and missed the start of it. I did manage to get a short video which included one of the oldest tractors I have ever seen.

Hyaaaa, Mule!

Over the river and through the woods to the Progressive Homestead we go! We never made it. There were two huge distractors in our way. Meet Pam and Pat, two very large – did I say very large? – mules! Once again, I stayed as far back as I could. Not because of their size, okay I lied it was because of their size. Pam, Pat, and one of their owners, Freddy Simmons, gave plowing demonstrations.

And again here comes our 7-year-old. Chip just had to get in on the act. After some convincing, he was able to talk Freddy into letting him try his hand at plowing the half acre field. So he was harnessed up and off he went. You would be amazed at how quick these mules move! Chip later said, “Once I got the hang of it, it wasn’t that bad. The mules do most of the work, but the hard part was getting the mules to turn.” Freddy was next to them the whole time. I am sure he was more concerned about the mules than our host.

Sheep Shearing

What’s next? Sheep shearing of course. This was a very popular attraction. I was amazed at the size of the crowd and could not get close enough to take a lot of pictures. The poor sheep was tied to a table, but didn’t make a sound – bless its heart.

The groomer used a large barber clipper and off came the sheep’s coat. To me it looked extremely painful. I later found out it really does not hurt the sheep.

The sheep, after it is over, actually likes it. It keeps them cooler for the summer. Never thought about it that way. It totally makes sense.

Chip was able to help hold the sheep down, but could not actually sheer the poor thing. A very good call on the sheep shearer’s part — that poor animal might have ended up with a mullet haircut instead of a proper trim. That 7-year-old thing…

Remember I said I could not get close enough to the sheep shearing action? Well by now you know me and how I wander around. So off I go to look at a cow – no big deal right? Guess again. There was a something very different about this cow. It had horns, but female parts as well. Very confusing. I have a tendency to talk out loud and was overheard by a woman standing next to me. So my lesson began. She explained to me that some female cows are born with horns and they are sawn off. What?!? Have you ever heard of such a thing?

Once we got home I forgot about researching this. But, an opportunity to verify this information presented itself at the Gibbs Family Farm in Abbeville, GA, where we were weeks later to film another future episode of WTFCF. Not to give away too much about that episode, I will only share the answer I got from the Gibbs.

I asked one of the Gibbs teenage daughters, who raise their herd of 300 cattle, about this girl cows with horns thing. She said, “It’s rare, but it happens.” She told me if the horns come up, they have to use a special tool to cut them off. Sometimes the horns grow inside next to the cheeks. They definitely have to be cut out or more problems can happen. I guess we can compare this to an impacted wisdom tooth. I really did not want to know the gory details and quickly changed the subject.

Trial By Fire

You may think by now our day would be winding down, but no such luck. Led by our 7–year-old, we headed toward the belly of the dragon. At this point you are probably saying, “Really, Donna!” Well, it felt like it — you would have had to have been following Chip around all day to understand (and it’s pretty clear from the episode what kind of danger he kept leading us into!).

This stop was a large, dark, three-walled area with a hot potbelly stove in the back of it shooting out flames! OK, that may be a bit of an exaggeration, but between that and the weird looking tools hanging all over the place I was worried.

Welcome to the blacksmith’s shop. In my opinion this is probably the most important part of a farm and village. If this shop was not here, the tools needed to run all the great places we visited would not exist. No levers for the sawmill, no spatulas for the turpentine mill, no harnesses for the mules, and no chains for the grinding wheels at the gristmill.

Blacksmith working at the Georgia Museum of Agriculture, Credit: Garret Boone

Greg Tucker, volunteer and reenactor, greeted our 7-year-old. Now I might mention, Chip is a bit of a pyromaniac and could not wait to get his hands on all this stuff. Greg welcomed Chip with a little apprehension — he probably heard about him breaking the saw at the sawmill but let him in anyway.

He explained how the shop works and what a few of the tools were used for. The most important tool is the blacksmith’s hammer. It is a type of sledgehammer where one side of the tip is rounded to shape the red-hot steel against an anvil. Greg gave a great and very loud demonstration of removing the hot steel from the stove and pounding into what would be a horseshoe.

Now it was Chip’s turn. Greg pulled a glowing piece of steel out of the oven and put it down for him to pound. With a big grin on his face, wearing a pair of gloves, and with hammer in hand; Chip began pounding his little heart out. He did not shape the steel into anything useful or recognizable, but you can tell he had a great time.

After much to-do we were able to tear Chip away. This was not easy — after all, a blacksmith’s shop is a great place for a pyromaniac to play. He had his fun and it was time to join the rest of us. He was happy, but very hot and sweaty. (Side note: his right arm paid for it the next day.)

The Grist Of The Situation

At that moment, I was paged to go somewhere else, where I don’t remember. Garrett gave me directions and his cell phone number, just in case, on how to get to our next stop the Davis Grist Mill. Naturally I got lost and had to call Garrett to come and get me. Honestly, that was pretty embarrassing.

Remember what I said about the paths looking a little dangerous for me to walk on? Well… I was right. The paths took us through the woods and up a hill which was bad enough, but then a large steep stone staircase with narrow steps loomed before me. Ugh, another no bueno. But I finally made it.

The crew was busy setting up cameras inside the mill and Chip was talking to Blaine Holbrook, another volunteer. Blaine talked about all the side hustles the people of that era had. Naturally, this included making the moonshine. I have tasted it in my life, but have not been impressed (Chip says that’s because I’ve never had any that was actually any good…). Some of the side hustles were pretty dicey — my brain was giving out so I don’t remember all the details.

One sticks out: Any gristmill is built on a stream. Streams have fish. Those streams are funneled into a narrow sluice for a gristmill. We saw a weird, rectangular wooden box that looked like it had a row of teeth on one end.

It was a fishtrap! The millers dropped these in their sluices and collected all the fish they could use! Of course, that also meant people downstream didn’t have any fish to catch… so they had to buy them from the miller. See what I mean by side hustles?

So sorry — back to the actual gristmill.

You all probably know the purpose of a gristmill. Basically the gristmill is powered by a waterwheel and uses two grinding stones to grind grain into flour or meal. I wondered if any of it was gluten free. Some of us need that! [EDITOR’S NOTE: Corn meal!]

Anyway, the gristmill is also very dark place, set on a stream, meaning it is very cool inside. After the blacksmith’s shop this was a relief. Chip, Sam Roy (pictured left), and Mr. Jonny Fordham (pictured right) – both volunteers and reenactors – climbed into a hole where the grain is collected and just talked. Both men were extremely knowledgeable, but Jonny had the most experience and was able to explain the workings to a T.

All Aboard!

What trip to an Ag Fair would be complete without a steam train ride?

Our conductors were Brock Fitzgerald and Brian Dowd. They are both extremely young. Very impressive. While most young men are running around doing who knows what, these two trained to become conductors and engineers and reenactors.

This particular train is the Vulcan Steam Train Number 5, built in 1907 in Columbus, GA. The first section of a train is actually the locomotive. I always thought the whole train was considered the locomotive. Who knew? I don’t have any personal pictures; I was once again holding a camera, this time on the platform, with the heat and the smoke and the cinders from the train blowing in my face. Fun.

The whole area was very loud. I saw everyone sweating. It must have felt like an inferno while they were stoking the fire – to create the steam – that runs the train. This is where the interview took place with Brock and Brian. Again, I could not hear the details because of the noise, but Chip did say, “That’s the hottest place I have ever been, including Mexico in July.”

Can you imagine it was even hotter than the blacksmith’s shop where the potbelly stove was spewing flames? But with passengers all aboard, off they went! Where to I don’t know — remember, I was still stuck on the platform.

While I was waiting I did peek into the building behind the platform. It was filled with more tools and other stuff from that period. I guess backups if things break during the demonstrations or for new exhibitions.

Before we knew it, dusk was approaching. It was a long, but really fun day. We did not even cover all of it and could easily have spent three days there. But that would make for an even longer “Behind-the-Scenes” article. I really don’t know if I would have the energy for that. You may not either.

But I have a feeling we will be back in Tifton to tell more of this story.

There are always classes and exhibitions going on at the Georgia Museum of Agriculture & Historic Village. It is a great family experience and I highly recommend it. I can’t wait to go back with some of my grandchildren in tow.

Oh, one more thing. Remember the sirens we heard at the gristmill? As it turned out, the firetruck next to the turpentine mill — remember the mill that could blow up into a mushrooming fireball at any moment? — had to leave.

The funny part about that? The firemen left their hoses behind, just lying on the ground as they pulled away.

I do hope they didn’t need those later…

Watch Part 2 here