It’s not Room 222, remember the comedy-drama that ran from 1969 – 1974? Turns out it is actually Room 210 at Clemson University. The time is 4 a.m. What a ghastly hour! So what were we doing here? Hold onto your hair nets – making blue cheese of course with Clemson Cheese Master Anthony Pounders!

Where The Food Comes From visited Clemson University in Clemson, SC on June 20. Clemson has been making Blue cheese since 1940 and the tradition holds strong. At that hour in the morning dedication truly becomes a must. Personally, I don’t think I could do it three days a week.

Cheese Master Anthony Pounders

As we were approaching Clemson the road was lined with orange paw prints. Turns out Clemson’s mascot is a tiger – in case you were wondering the tiger does not have a name – and the paw prints lead right to the university.

We were greeted in the parking lot by Cheese Master Anthony Pounders. We were told in confidence we really could have started at 5 a.m., but it is what it is. And it was well worth it.

Blue cheese making is a slow process and a lot of time is waiting around for one culture or another to finish processing. So sit back and enjoy my version of how to make Clemson Blue Cheese.

The cheese making room looks like a sterile and shiny operating room with a large tub off to one side. This is where the magic happens. The vat you see in the above picture is filled with pasteurized milk. Okay folks hold onto your hats for the next sentence because it’s a mouthful. The milk is waiting for a starter culture – a lactic acid bacterium – to be added to change the lactose in the milk – a natural milk sugar – to create lactic acid. Hope you got through that.

Lactic acid is what causes the cheese to solidify. Fun fact: The milk actually comes from the Dorn’s of Hickory Hill Milk, Season 4, Episode 3: Robot Dairy. The Dorn’s have been supplying Clemson the milk to create this magnificent cheese since, I believe, 1986. As you can see Anthony is making sure the starter culture is well mixed. Let’s go and check it out.

With anything, maintaining appropriate temperature is important. There was a problem earlier that day, yeah believe it or not before 4 a.m. New equipment was being used and a breaker flipped. Chip, being very diligent, was keeping an eye on the electrical box while Anthony stirred the starter culture. Thank goodness all breakers held.

Anthony has to monitor the temperature of the milk before the starter culture is added. Using a hand held thermometer he is making sure the milk is approximately 72 degrees. Lucky for us it was and in goes the starter solution. Rennet is also added to help speed up coagulation. Ready for a time check? It’s a skosh past 4 a.m.

As the paddles are stirring what is actually happening is the milk is solidifying creating ready for this? Curds and whey. Well, I am no Little Miss Muffet. Eating curds, the solid form of the process, and whey, the liquid form, really does not sound appealing. I think I will wait for the blue cheese.

At this point you are probably wondering what makes blue cheese blue? A fungus called Penicilliun roqueforti is also added as the curds and whey are beginning to form.

So, let the stirring commence and the waiting begin!

Time check 6 a.m. Say hello to the student cheese making assistants. I had to find out why they are there so early. Turns out they are all morning people and prefer to come to their jobs early instead of after their classes. All of them have different majors and they love the fact that they have met some of the wonderful students on campus they otherwise may not have. What is their job? To pull the curds from the milk vat and put into the molds. More about that in an hour or so.

Time to meet the second in command Assistant Cheesemaker Crosby Jack Sackett. Their interview took place in the aging cooler fondly known as the cave. It is in the cave the blue cheese begins the aging or ripening process. Crosby told us for the final aging process blue cheese needs to sit in the cave at 42 degrees and with 90% humidity for at least two to five months. Fun fact: Long ago and far away blue cheese was aged in real tunnels. This interview didn’t last too long. Chip hates the cold and did not have his bulldog sweatshirt with him.

Another interesting thing we learned was about lot numbers. Anthony and Crosby keep very close tabs on this. A lot number is pulled and prior to shipping it is checked for Listeria, Salmonella, and Escherichia coli (E. coli). Pretty cool. Really reduces the chances of someone getting sick. But, should this happen they will recall that particular lot number. Back to the blue cheese, I warned you it was a long process. Remember the paddles in the milk vat have been turning this entire time, but it gave us a chance to get some more interviews in.

Time check 7:22 a.m. We were able to find a nice, quiet and well-appointed room for Chip to speak with Anthony. The blue cheese products were arranged on a table. All I could think about is when we were going to get to sample it. Remember, we started at 4 a.m. and no body ate breakfast.

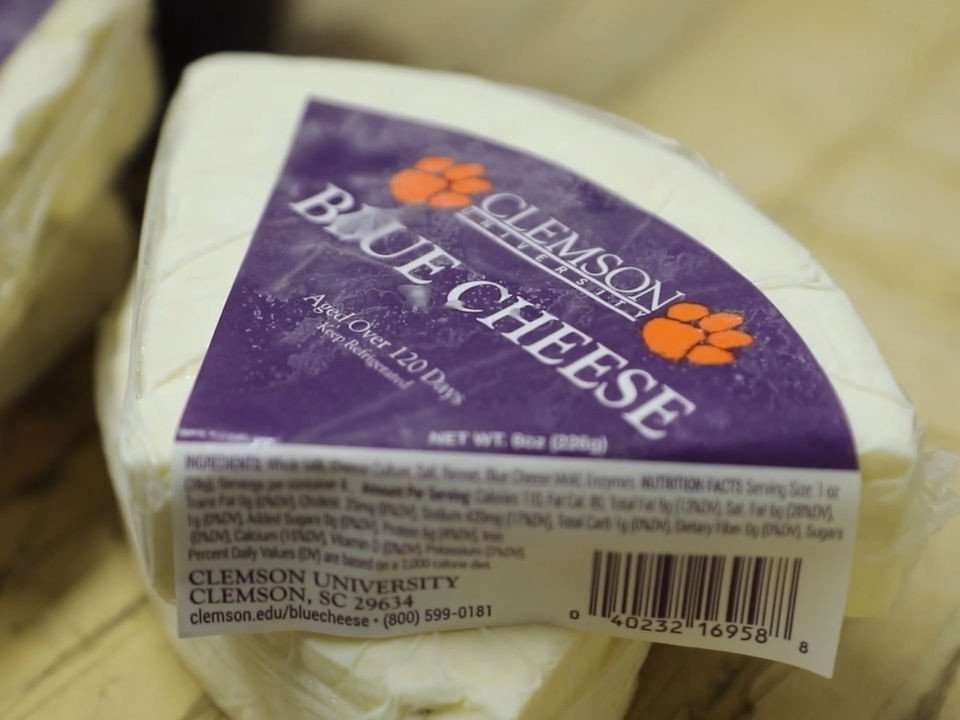

A little more history was discussed. Anthony told us 85% of the blue cheese is shipped out. Clemson Blue Cheese is sold throughout South Carolina and the Southeast. What about the rest of us? No worries, you can purchase it at clemsonbluecheese.com. As you would expect the busiest time of year is Christmas. So get it while the cave is full!

Time check 7:56 a.m. Finally, we are going back to the milk vat.

As you can see our student workers are all present and accounted for and the whey is slowly draining from the milk vat. The stirring paddles have been removed and the curd grates are on. The curd grates are sifting through to make sure there are no large pieces and if there are they are manually smashed into smaller pieces. Honestly, I don’t know why I don’t have a picture of that. It’s one of those things where one picture is worth a thousand words.

What happened next moves so fast. The students were shoveling the curd out of the vat, throwing it on a sterilized table while the other students were scooping it into the molds. I am so glad I was able to get this video.

At last the cheese is in their molds. Next stop? The cave. And once all the blue cheese molds are moved out the room is disinfected and sanitized. Food safety, like everyplace we have been, is always a major priority. Per Crosby, “Never assume you are safe.” In case you’re wondering time check 8:23 a.m.

Finally, we got to taste the blue cheese and it was awesome. Believe me, I will be ordering some for our kids for Christmas. You may want to too.

Time check 9:10 a.m. Our day ended with Chip interviewing Kinnley Coffman and Elyse Corbin. Remember I said the students all have different majors and because of this they don’t usually meet other students on campus? Here is an example. Kinnley’s focus is Industrial Engineering and Elyse is working on her masters in Biochemistry. They discussed what the school and working with the other students making blue cheese means to them.

With Kinnly and Elyse, Chip closed the show. This was a bit weird for all of us. We don’t usually end a shoot before 5 p.m., but to be fair we don’t usually start at 4 a.m. The crew went into the lobby of the building to collapse. Boy did we have a surprise waiting for us.

Two ladies came out of another room with a glass front – ironically none of us bothered looking into the room to see what was happening – and handed us ice cream cones. What!! We didn’t know Clemson made ice cream too. I think we may have found a future story. Time will tell and hopefully it will not start at 4 a.m.